Precision Laser Solutions for MROs and A&Ps

Discover our advanced laser ablation technology that cuts costs and minimizes downtime. Whether you need services to your site or looking for a turnkey solution and training.

Safer, Faster, Cleaner

Aviation Laser Services at the NBAA Maintenance Conference

Had a great time at the conference in Columbus, OH. Met a lot of great people from MROs like Textron Aviation, AV8 Group, S.E.A.L. and SWAT, and fleet aviation maintenance executives at Kroger, NetJets, Cardinal Health, Exxon, and many others.

Advanced Laser Cleaning with the FeatherPulse FP-300 for Aircraft Surface Restoration Revolutionizing Maintenance, Repair, and Overhaul (MRO) Operations

Summary

Aircraft surface restoration is a critical yet labor-intensive process in aviation maintenance. Traditional methods—mechanical abrasion, chemical stripping, and media blasting—pose risks of substrate damage, hazardous waste generation, and inconsistent results. The FeatherPulse FP-300, a 300W pulsed fiber laser system from Aviation Laser Services, offers a transformative solution. By leveraging selective ablation and micro-spallation, it precisely removes paint, primer, sealants, and corrosion from aluminum and composite substrates without damaging underlying materials. This white paper explores its technical specifications, safety protocols, performance advantages, and validated economic benefits, supported by case studies from the U.S. Air Force and FAA-compliant MRO facilities.

Introduction: Challenges in Conventional Aircraft Surface Cleaning

Aircraft maintenance mandates meticulous removal of coatings and corrosion to comply with Structural Repair Manual (SRM) limits, ensure adhesion of new coatings, and enable nondestructive inspection (NDI). Legacy methods face significant limitations:

Mechanical Cleaning: Manual grinding risks gouging substrates, embedding particulates in fatigue-critical zones.

Chemical Stripping: Alkaline/acid solvents demand hazardous waste containment and PPE, increasing downtime.

Media Blasting: High-pressure abrasives risk delamination, require secondary cleaning, and generate airborne contaminants.

These methods are labor-intensive, environmentally taxing, and often incompatible with modern composite materials.

Operating Principles

Selective Ablation: Nanosecond pulses vaporize contaminants (paint, oxides) while reflecting off aluminum/composite substrates, limiting heat transfer to <120°F, ensuring precision and substrate integrity.

Micro-Spallation: Laser-induced stress waves dislodge corrosion products from rivet lines and tight geometries, achieving Ra ≤1 µm post-clean, preparing surfaces effectively for subsequent inspections or coating applications.

Performance Advantages Over Conventional Methods

-

Material Removal Rate: 400 mm²/min (automated) versus traditional manual methods at 0.05–0.5 mm²/min.

-

Base-Metal Loss: Minimal (<1% thickness loss), preserving component structural integrity.

-

Surface Roughness: Achieves Ra 0.8–1.2 µm, ideal for coating adhesion.

-

Operator Safety: Enclosed system with HEPA and activated carbon filtration, eliminating exposure to hazardous chemicals and airborne contaminants.

-

Environmental Impact: Produces zero secondary waste, significantly reducing environmental footprint.

-

Inspection Readiness: Enables immediate eddy-current and visual inspection without additional cleaning steps.

Safety, Quality, and Certification

Infrared Monitoring ensures surface temperatures remain ≤120°F, preventing thermal distortion and maintaining substrate structural integrity. The advanced filtration captures 99.95% of particulates (HEPA) and volatiles (activated carbon), validated by trials detecting no hexavalent chromium during zinc chromate removal.

Case Study: FAA-Compliant Corrosion Pit Remediation

Challenge: Traditional corrosion pit remediation on 7075 aluminum panels involved significant labor and risked exceeding thickness limits.

FP-300 Solution:

-

4 passes at 250 mm/s resulted in only 2.1% metal loss versus 15% using media blasting.

-

Laser-induced microhardness enhancement by 8.45% due to grain refinement.

-

Passed MIL-C-81706 conversion coating adhesion tests within 8 hours.

Outcome: Achieved 60% faster processing, significantly extended component lifecycle, and secured FAA approval for in-situ repairs.

Substrate Performance Enhancements

Laser cleaning significantly enhances substrate properties:

-

Corrosion Resistance: Nanostructured oxide layers (MgO/Al₂O₃) improve uniformity, reducing corrosion current density by 40% compared to mechanical methods.

-

Welding Quality: Laser cleaning in argon reduced porosity in AA5083 welds from 9.68% to 1.59%.

-

Adhesion Strength: Surface roughness and oxide layer activation enhance paint adhesion by approximately 30%, improving coating longevity and reliability.

Economic and Operational Benefits

-

Labor Savings: Single-operator setup versus 3–5-person blasting teams.

-

Downtime Reduction: Processing large areas 2–5 times faster, significantly enhancing turnaround times for critical assets.

-

Lifecycle Extension: Reduced metal loss preserves fatigue life, lowering replacement and repair costs by 20–35%.

Regulatory Compliance and Future Integration

FAA/EASA Certification: Demonstrated compliance through AFRL trials on F-16s and B727s, meeting stringent airworthiness directives. Robotic Integration: Compatible with automated cells for high-volume, repeatable, precision-based MRO workflows. AFRL-supported robotic laser coating removal for F-16 aircraft significantly improves efficiency, safety, and environmental compliance.

Conclusion

The FeatherPulse FP-300 delivers revolutionary precision, safety, and economic efficiency for aircraft surface restoration, surpassing traditional methods. With demonstrated compliance and operational benefits verified through AFRL-supported applications, the FP-300 positions Aviation Laser Services as a leader in innovative aerospace MRO technology.

A real-time look at what the FP-300 can do for your MRO business.

20+ Years as A&P and IA Endorsement

Removing Corrosion from Tight Places Easily

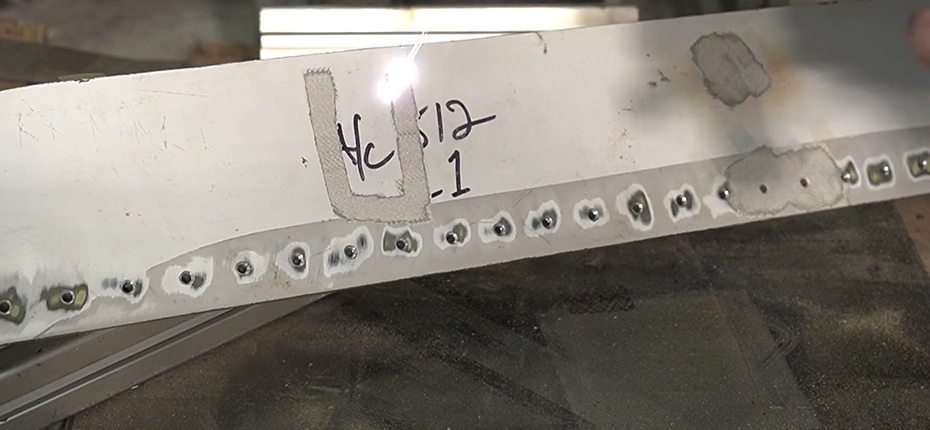

Quick, Safe, Clean removal of paint along control surface rivets

Corrosion Removal - Control Surface

Blast Media v. Laser

Landing Gear Parts

Get our Newest FP-300 Compact Laser for the same price as our trolley model delivered to your facility for only 50% down.

Once delivered and Zoom training completed you can pay the balance.

If for some reason you don't find it useful for your operations after delivery we will refund your deposit less a $1500 cancellation fee.

DESIGNED AND ASSEMBLED IN THE USA

Call us for more info and current pricing:

479-588-1200

100% U.S. Based

Sales

Service

Technical Support

Warranty Claims

Warranty:

2-Year on Laser Module

1-Years on Everything Else

Life Expectancy: 50,000 - 75,000 Hours

Dimensions: 24.75"H x 27.5"W x 17"D

Solving Problems with Current Traditional Methods

APPLICATIONS

Laser Cleaning

Efficiently remove paints and coatings from aircraft components with micrometer precision. No damage to underlying material. Enhance productivity in maintenance operations.

Coating Removal

Remove coatings from aerospace parts quickly and effectively. Maintain material integrity and surface quality for superior performance and durability.

Surface Prep

Eliminate rust from aircraft components to prevent corrosion and ensure structural reliability. Enhance the lifespan and safety of aerospace equipment.

Rust & Corrosion Removal

Prepare surfaces for bonding and welding processes with precision and consistency. Ensure optimal adhesion and structural integrity of aerospace components.

Rivet Line Ablation

Photo Credit: Aviation Laser Services

The FP-300 FeatherPulse laser offers an efficient solution for cleaning aircraft wings, particularly along the rivet line. This cutting-edge laser technology effectively removes paint while protecting the rivets, ensuring no material is compromised. By reducing risks like heat build-up and the possibility of over-removing rivet heads, the FP-300 plays a role in preserving the aircraft's integrity and safety. Opt for the FP-300 for a and more effective cleaning approach.

Avoid rivet damage from sanding or heat build-up

The U.S. Air Force uses lasers to remove paint from aircraft. These methods are safer and more efficient than traditional methods. [1, 2, 3, 4]

-

Heats the surface to pop off the paint

-

Is safer than sanding, which requires more personal protective equipment

-

Is faster and reduces labor costs

-

Is approved for use on specific aluminum and graphite epoxy composites

-

Is being investigated for use on other materials and air platforms

Footnotes

Textron FP-300 Analysis

Scientific Study

Corrosion and Wear Performance of Aircraft Skin after Laser Cleaning

[1] [excerpt]"The fretting friction and wear performance of aircraft skin rivet holes after laser paint stripping with different energy densities was studied, the friction and wear performance of other parts of the skin were studied and compared with mechanical grinding and laser paint stripping. The results showed that the laser did not reduce the friction and wear performance of any part of the aircraft's skin surface. The residual stress, micro-hardness, and corrosion performance of the aircraft skin surface after laser paint stripping were studied. Compared with the mechanical lapping and laser paint stripping method, it proves the laser will not reduce the hardness and corrosion resistance of the aircraft skin."

Version of Record: https://www.sciencedirect.com/science/article/pii/S0030399220311087

© 2020 published by Elsevier. This manuscript is made available under the Elsevier user license https://www.elsevier.com/open-access/userlicense/1.0/

Coming Soon!

2027

AI Powered Laser and

Robotic Technology

Industry News

Our Partners

Collaborative Relationships

We value our partnerships with industry leaders, working together to deliver high-quality services and innovative solutions. These collaborations enable us to provide comprehensive aerospace maintenance and refurbishing services, ensuring excellence and client satisfaction.

T&P Aero Refinishers

Salinas, CA

B-B Aircraft Services

Mena, AR

Current Service Area Map